About Thermoelectric Cooler

Peltier element and Peltier effect

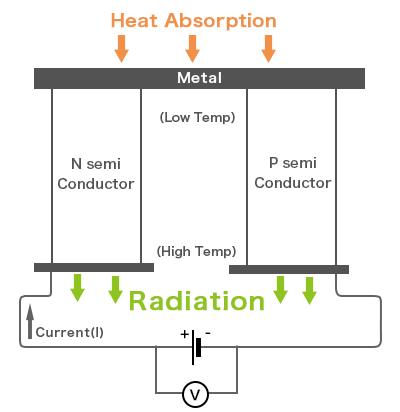

A thermoelectric moduleis a semi-conductor element that enables cooling, heating and temperature control to be freely conducted with a direct current.

Also called

- ●Thermoelectric element

- ●Thermoelectric device

- ●Semiconductor device

- ●Peltier element

- ●Thermo module

- ●TEC

By putting a direct current through a thermoelectric module, the following capabilities can be exploited.

- •A temperature difference occurs between the sides of the module.

- •The low temperature side has an endothermic effect, and the high temperature side has an exothermic effect, so that heat will transfer from the low temperature side to the high temperature side. In other words, it functions as a heat pump.

- •It is possible to reverse the direction of the heat pump by simply reversing the flow of the current, and further it is possible to change the rate of heat transfer by altering the size of the current.

This is a simple method of cooling, heating and temperature control.

Evolution of Thermoelectric Module

The Peltier effect was discovered more than 170 years ago in 1834, and was established theoretically in the early 1900’s, but due to the fact that metallic materials were used the efficiency were limited and not suited to practical applications. It was first applied to electronic cooling in the 1960’s when semiconductor materials became available, and electronic cooling elements with a decent level of efficiency could be produced.

Features of Thermoelectric Cooling

Compared with standard designs using refrigeration cycles with compressors and cooling mediums(such as CFC’s), thermoelectric cooling possesses the following traits:

- 1.Environment friendly since no cooling medium such as CFC’s is used.

- 2.Compact system.

- 3.Flexible form.

- 4.By simply changing the current polarity, heating is possible in addition to cooling.

- 5.Since cooling and heating are both possible, it is easy to regulate temperatures close to room temperature.

- 6.Short response time (Quickly heats or cools)

- 7.Since there are no moving parts, there is no vibration or noise.

- 8.Since there is no fatiguing or breaking machine parts it is the most long-lasting, reliable method of cooling.

- 9.With only a power cord, it is easy to handle.

- 10.There is no worry of coolant gas leakage or corrosive gas leakage, meaning that maintenance is easy.